Kaizen is a Japanese word that means Continuous Improvement. It describes a management philosophy that embraces small but continuous changes to the workplace as opposed to infrequent large company reorganizations. In the long run, Kaizen brings better results.

Kaizen characteristics:

- Continuous elimination of waste.

- Ideas do not have to be great technological inventions but small changes that make work easier, safer and more productive.

- Solving problems using common sense.

- Immediate implementation of improvements.

Kaizen is supported by teamwork and by direct participation of managers in improvement activities. To sustain continuous change engagement of all employees in the plant is required. Therefore, Kaizen breaks down organizational barriers and enables operators to influence the way they do their work.

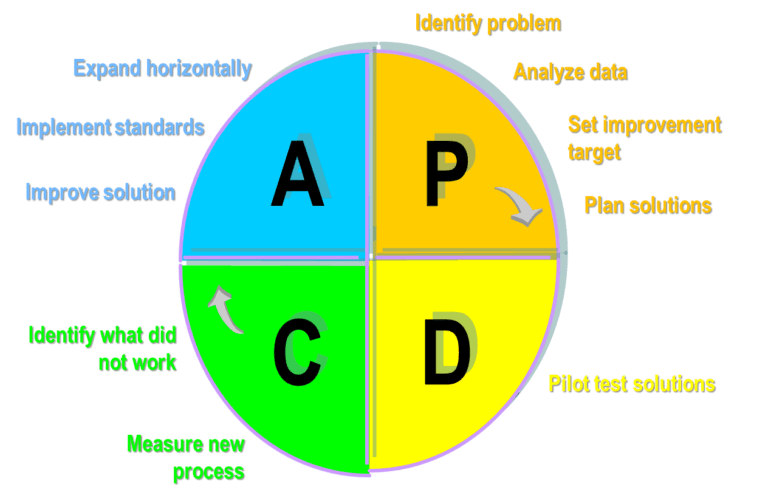

PDCA

Plan-Do-Check-Act is the most used method for solving simple problems. Usually also known as Deming’s Circle, it allows to plan and implment straightforward improvements in Kaizen:

Plan – establish targets, analyze the problem, propose a solution.

Do – pilot solution on a small scale.

Check – if the solution achieved desired results vs. target.

Act – modify the solution based on findings in Check, standardize and spread horizontally.

Kaizen Blitz workshop

Also known as Hoshin Kaizen, during a few days of team activities related to brainstorming, planning and implementing of improvements can dramatically improve productivity in a manufacturing cell or on a an assembly line.

The workshop begins with a training on Kaizen. Using learned techniques, the team analyzes the process, identifies waste and documents the current state. Then, during brainstorming, ideas for improvements and an implementation action plan are developed. Typically, most of the improvements are implemented during the workshop. The new process is documented and standardized. The workshop ends with a presentation of results before management.

A distinctive feature of Kaizen Blitz is immediate implementation of improvements. After the conclusion of the workshop, the area is returned to production in a new state. A typical Kaizen Blitz result, for example in a production cell, is to create a new layout that reduces space, improve work organization and increase productivity, reduce inventories in progress, shorten the time of process and cycle time, and many other benefits.