Value Stream Mapping is a tool for visualizing a flow of production processes and information interactions therein. Consequently, mapping begins with creating a Current State to identify wastes in these processes. Generally, analysis of these wastes allows to develop a change plan based on Pull System principles. A new vision is then recorded on a Future State Map, together with an implementation action plan.

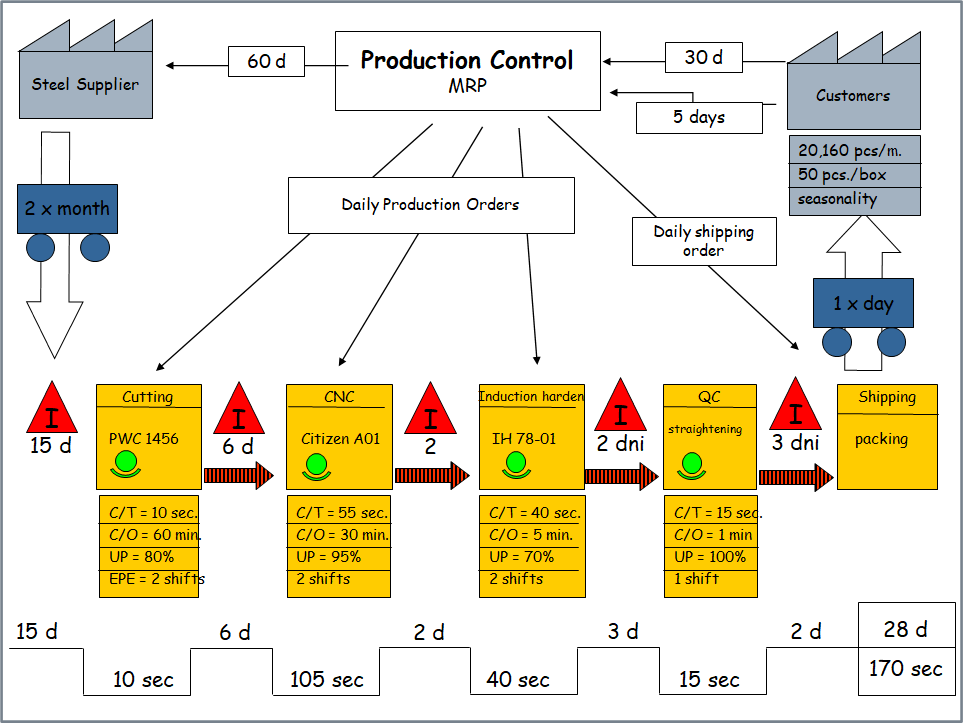

Current State Map

The map identifies wastes in the production process: unbalanced operations, inventory, long changeover times, machine breakdown rates, etc. Also, the map shows supplier links and identifies major customers and their combined demand. To avoid clutter, a separate map is created for each product family, defined as groups of products that are processed on the same workstations.

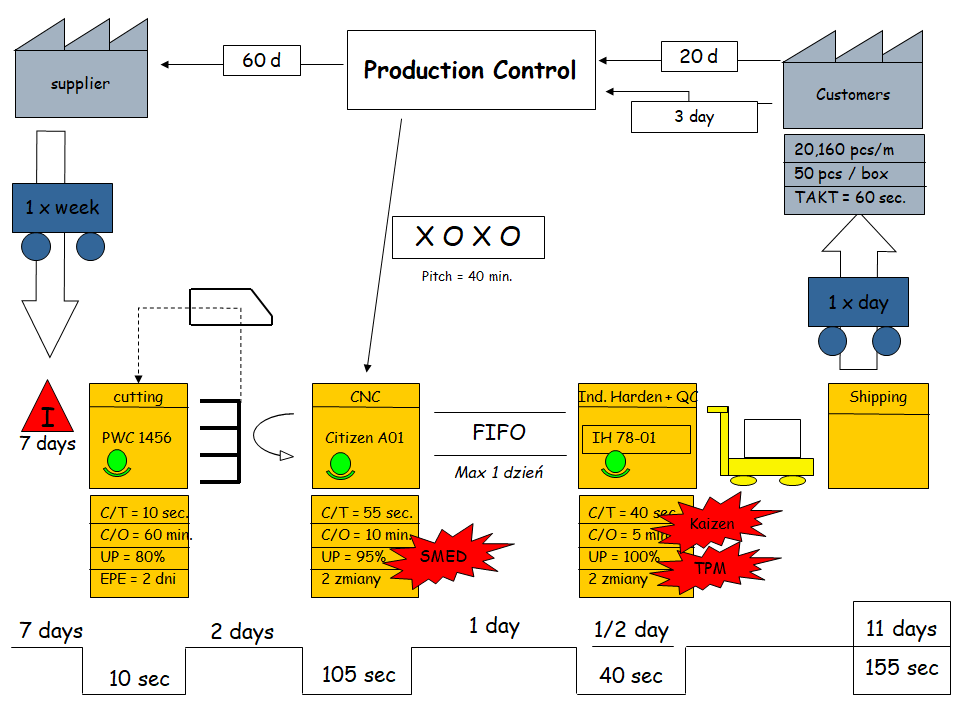

Future State Map

Identifies possibilities of implementing Pull System by reducing changeover times, introducing Supermarkets, Kanban, Heijunka and other improvements in the production process.

Steps to develop a Future State

- Determine strategy for finished goods: produce to order or to stock from which customer needs will be served.

- Join manufacturing processes to minimize throughput time and reduce WIP, where possible.

- Implement FIFO or Supermarkets for WIP where linking processes is not possible.

- Identify the Pacemaker – a process that sets the pace of production.

- Define the Interval: the frequency with which same products will be produced.

- Calculate Supermarket size and quantity of Kanbans.

- Determine Heijunka and Pitch – how and with what frequency information will be sent to the Pacemaker about what to produce next.

VSM Workshop

The purpose of the VSM Workshop is to develop a plan to implement a Pull System. Participants take part in a two-stage VSM Simulation that illustrates differences between Push and Pull. The simulation also teaches how to calculate Supermarket size and quantities of Kanban cards. Also, where to install FIFO queues, how Pacemaker, Heijunka, Interval, Pitch function and many other advanced Pull System concepts.

During the practical part of the workshop, a Current State Map is created for one product family. Subsequently, a brainstorming session develops a Future State Map showing the future vision of operating the production process using the Pull System principles. A PDCA action plan for implementing changes completes the workshop.

Literature

A classic beginner’s book on Value Stream Mapping: Learning to See.

Advanced reading: Creating Mixed Model Value Streams