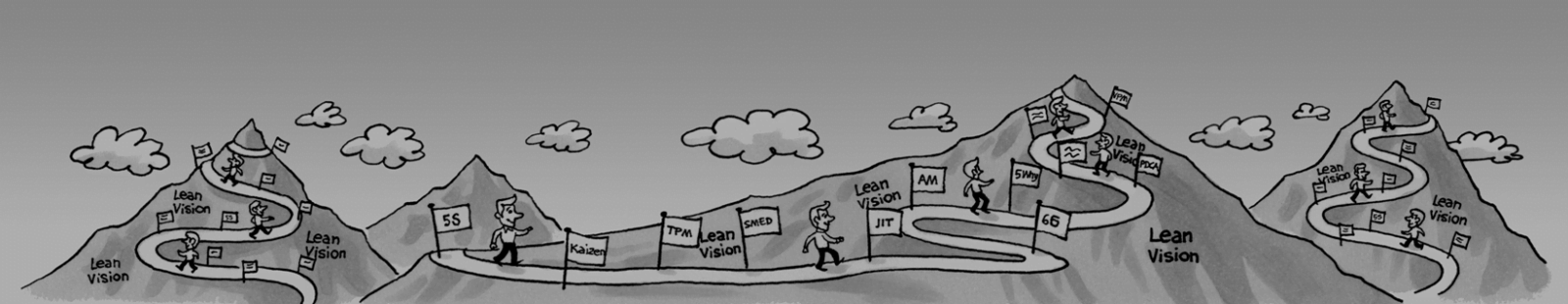

Visual Performance Management (VPM) supports 5S in creating a visual work environment. VPM provides up-to-date information on process performance, enables real-time problem solving and ensures continuous improvement.

Management Cycles

- Operator’s Cycle – analyzing hourly production performance and problems with equipment

- Leader’s Cycle – End of the shift meeting with operators to discuss results and prioritize preventive actions

- Production Manager’s Cycle – daily meeting with production leaders and managers of the supporting departments to proritize resources for implementation of preventive actions

- Plant Manager’s Cycle – daily or weekly meeting with managers to prioritize continuous improvement activities and ensure availability of resources

SQCDME categories

Visual Management is based on data analysis. To ensure that KPI’s show process performance across multiple dimensions, consider creating metrics in the following categories: Safety, Quality, Cost, Delivery, Morale, and Environment.

VPM Workshop

The training is designed to introduce the participants to Visual Management and develop a plan to introduce this management system in own company.

Participants: max. 12 people

Length: 2 days, each day 8 hours.

Agenda

Day 1

- Review Lean Management principles

- VPM vs. traditional performance measurement system, selection of KPI’s in SQCDME categories

- VPM1 – operator’s cycle

- VPM2 – production leader’s cycle

- VPM3 – department manager’s cycle

- Brainstorming KPI’s for Tier3

DAY 2

- VPM4 – plant manager’s cycle

- Brainstorming KPI’s for Tier4

- Visual Management support tools: meeting agenda, action plan, escalation policy, RCA

- Brainstorming the implementation plan

- Quiz