Total Productive Maintenance unites production operators and maintenance specialists in joint actions against losses that reduce equipment efficiency. The goal of TPM is to achieve ZERO machine breakdowns, ZERO quality problems and ZERO work accidents.

TPM includes activities in five main areas:

- Focused Improvement – elimination of 6 Big Losses utilizing Problem Solving methodology

- Autonomous Maintenance – formal immersion of production operators in maintenance activities

- Planned Maitenance – developing a prevention system including periodic inspections, predictive activities, equipement improvements

- Training&Education – developing a prevention system including periodic inspections, predictive activities, equipement improvements

- Early Equipment Management – duilding a system that ensures design/purchase/production of equipment that is easy to use and maintain

Autonomous Maitenance

Autonomous Maintenance combines functions of operators and Maintenance Department in a joint responsibility for maintaining equipment in perfect condition. Operators gradually acquire specialist knowledge on the construction and operation of machines and, using their experience, take over some of the previous duties of Maitenance such as cleaning, lubrication and inspection. This allows skilled mechanics and electricians to spend more time performing scheduled maintenance, anticipating breakdowns and continuously improve machine performance.

Transferring knowledge to operators and their gradual inclusion in maintenance activities is divided into 7 steps. The program also features formal progress reviews.

Bringing a machine back to its original condition by finding and removing defects during general cleaning inside and out.

Identify and remove sources of contamination and hard-to-reach areas to reduce time spent cleaning machinery.

Establis preliminary standards for cleaning, lubrication and removal of equipment play.

Develop preliminary equipment inspection standards and train operators in their use.

Combine standards from Steps 3 and 4 to create an optimal inspection, cleaning and lubrication system. Reduce time required to perform tasks.

Develop inspection and quality control standards to be performed by operators.

Continuous improvement of developed standards, using KPIs to improve the process.

Planned Maintenance

Planned Maintenance creates a professional maintenance system focused on preventive actions. Implementation is divided into 7 steps:

- Prioritization and documentation of equipment, developing Key Performance Indicators – a measurement system

- Helping operators to bring machines back to new condition

- Systematic analysis of breakdown root causes.

- Developing an IT management system

- Creating standards for prevention and spare parts management

- Predictive Maintenance – using diagnostic tools to detect problems

- Using metrics to continuously improve the system

Impelementation of TPM

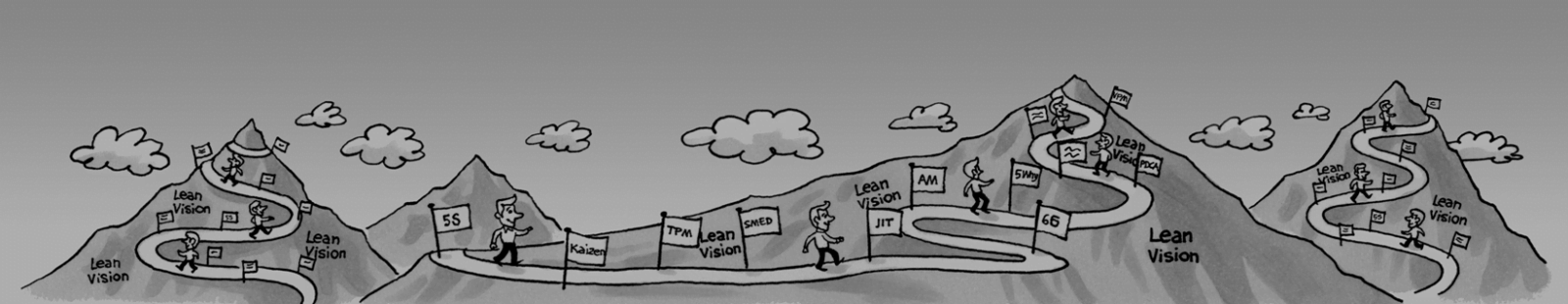

The Japan Institute of Plant Maintenance suggests dividing the TPM implementation program into 12 steps:

- Formal announcement of the decision to start the program

- Conduct initial training and information campaign

- Form implementation infrastructure: Steering Committee, Trainers, support personnel

- Develop an implementation policy and set goals

- Laying out the Roadmap (Master plan) for the project

- Program Kick-off ceremony

- Begin implementation of Focused Improvement, Autonomous Maintenance and Planned Maintenance on pilot equipment

- Implement advanced modules, according to priorities, e.g. Early Equipment Management

- Quality Maintenance – develop product quality standards

- Maintenance Prevention – create procedures to prevent the need to perform Maintenance

- Build a system supporting occupational health and safety and environmental protection (HSE)

- Extend the program to the entire organization and continuously improve

However, for most organizations implementing Operational Excellence using Lean Management methodology, TPM program will primarily focus on implementing Autonomous Maintenance and Planned Maintenance.

- Implementation of steps 1-3 AM on the pilot machine

- Implementation of steps 4-5 AM on the pilot machine

- Starting the PM deployment on the pilot machine, steps 1-4

- Implementation of steps 6-7 AM on the pilot machine

- Implementation of steps 5-7 PM on the pilot machine

- Extension of the program to other machines according to priorities

The TPM training presents foundations of Total Productive Maintenance, a system that ensures prevention and reduces machine breakdowns. It discusses the seven steps of Autonomous Maintenance, a program that involves machine operators in maintenance activities. Participants will also get acquainted with the elements of Planned Maintenance systematizing the work of the Maintenance Department: documentation of the current state, prevention system, elimination of sources of failures, etc. The basic metrics in TPM are discussed: OEE, MTTR and MTTR.

The practical part of the workshop focuses on the first three steps of Autonomous Maintenance: the participants dissemble main components of the pilot machine and clean all its parts in order to inspect and detect abnormalities. Sources of contamination and difficult to reach areas are also documented. At the end of the action, an audit of the activities is carried out and an action plan is drawn up to implement improvements on the machines and in the organization of maintenance.

Participants: max. 12 people

Length: 2 days

DAY 1

- TPM philosophy – history, comparison with traditional approach to maintenance, role of production and maintenance

- Autonomous Maintenance (AM) – presentation of the 7 steps to involve operators in the maintenance system

- Implementation of Step 1 AM – disassembly of the machine, cleaning of parts, inspection, identification of faults, sources of contamination, hard to reach places

- Creating initial cleaning standards and One-Point Lessons

Implementation of - Step 2 AM – 5Why analysis and planning to remove sources of pollution and difficult to reach places

- Implementation of Step 3 AM – setting standards for cleaning, lubrication of machines and clearance, assigning people and time

- Autonomous Maintenance Audit – assessment of the operation and condition of the machine, planning for corrective actions

- Measures of progress: OEE, MTBF, MTTR, calculation of indicators

- Introduction to Planned Maintenance (PM) – role of the Maintenance department in TPM, elimination of sources of breakdowns, improvement of machines, 7 steps of implementation, visual management of activities

- Preparation for PM implementation, equipment prioritization

Removal of breakdown causes, 5Why analysis, standard template - Creation of a review and prevention plan, standardization and visualization of activities

- Quiz to check understanding