Assessment Description

Lean Management Assessment analyzes the system of work in an organization and compares it to the best practices of World Class Manufacturing. The assessment is carried out in 12 categories that have critical impact on the company’s operational efficiency:

- Standard Work

- 5S

- SMED

- Zero Quality Control

- Autonomous Maintenance (part of TPM)

- Planned Maintenance (part of TPM)

- Just-In-Time

- Problem Solving

- Visual Performance Management

- Safety

- Supply Chain Management

- Organizational Culture

Expected assessment results

- Each category of assessment scored on a scale from 1 to 5

- Identification of good practices

- Suggestions for improving of less efficient practices

- Identification improvement potential, such as reduction in setup time or re-balancing of a production line

- Analysis of Value Streams and suggestions for improving process flow

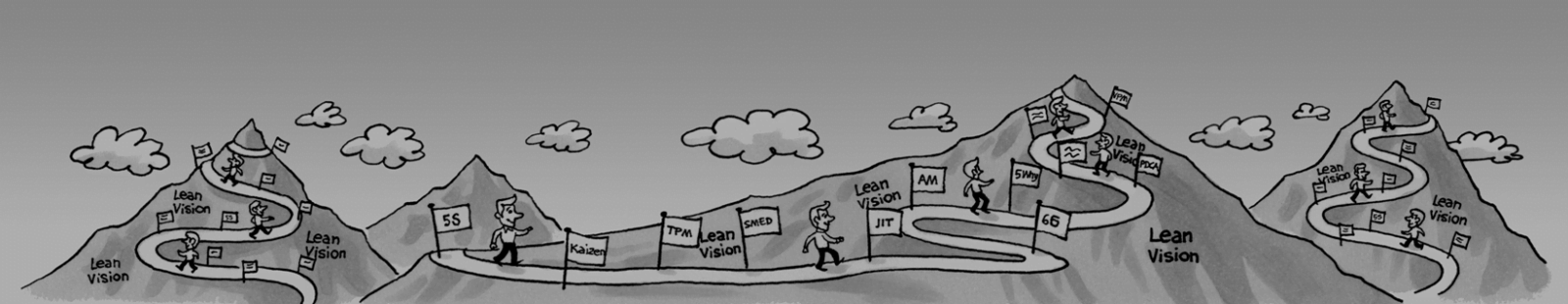

- Roadmap to implement lean methods

- Estimate of potential financial gains