Understand the real performance of your production equipment

Increase efficiency of the factory by automatically measuring and analyzing performance of machines, production lines and assembly cells. The system is designed and manufactured by a Swedish company Adductor murbox.com.

Advantages

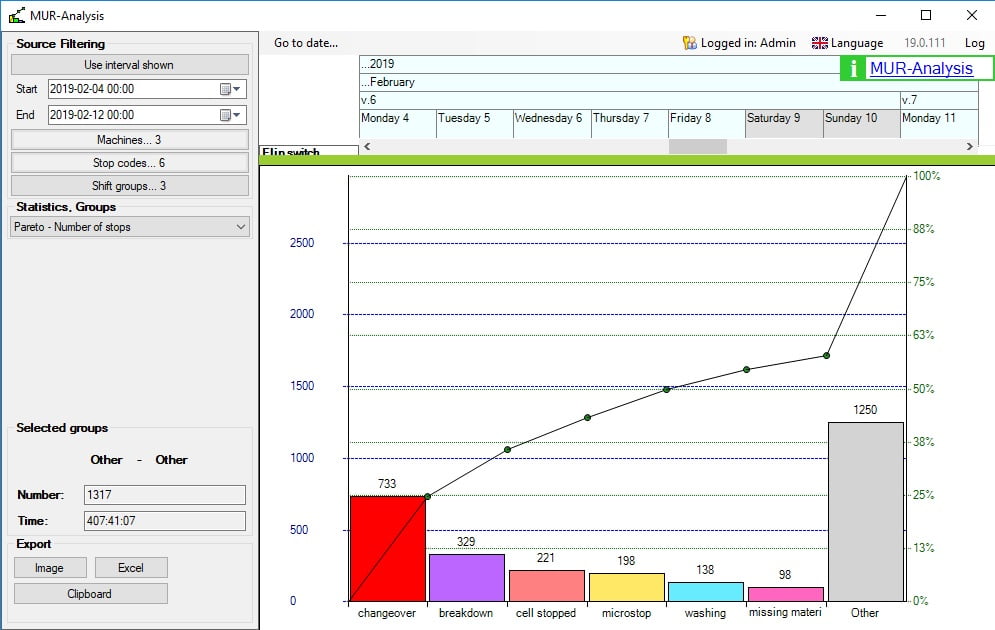

Pareto analysis of machine losses allows to optimize downtime reduction efforts. Possessing knowledge when there is a need to apply SMED (reduction of changeover time) or TPM (reduction of breakdowns) or Problem Solving (reduction of micro-stoppages) enables appropriate use of resources in the continuous improvement department.

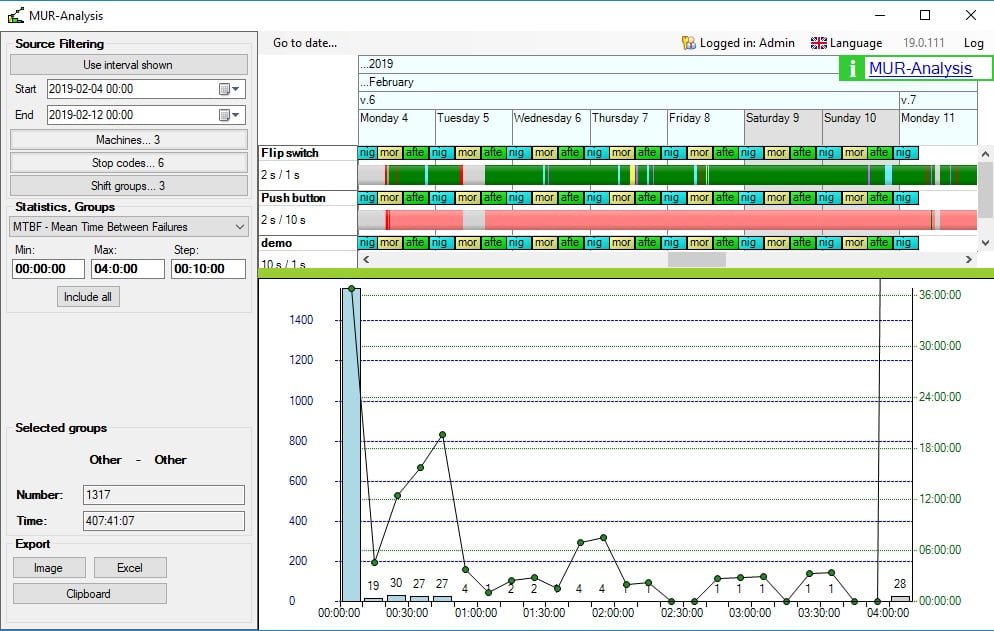

Overall Equipment Effectiveness (OEE) is a key indicator of machine performance. Together with MTBF it can show whether your loss-reducing activities result in better machine performance.

If provided with visual and real-time information on performance, a human will typically be more interested in the outcome of her work and the condition of equipment. Just displaying this information can frequently increase productivity by up to 20%.

MUR System is part of an intelligent factory where people and machines work together to ensure continuity of production. Being prepared for the upcoming progress in automation and information availability, you will be better able to compete in the marketplace.

Operation

MUR System constitutes a device connected to existing machine sensors that collect data on machine speed, production volume and downtime. This data is then sent via Ethernet or WiFi to an application residing on a windows computer.

The client application can be configured in various ways to show relevant information: current machine status, % utilization, Pareto of stoppages, hourly production output and more.

Everything is done automatically, with the exception of entering a downtime code on a keyboard connected to MUR or directly into a computer.

- Low cost solution, purchase or lease possible.

- Works with virtually any production equipment, manufacturing line or even assembly cell.

- Compact size of the controller allows for easy mounting.

- Simple and fast installation, without interference with PLC.

- Integration with ERP possible.

- Comprehensive remote support with installation and software configuration.

Installation procedure

Mount MUR controller near a machine, line or assembly cell. One MUR-box can collect data from up to twelve machines. A keyboard is used to enter stop codes by a machine operator.

MUR controller receives a signal from PLC or an external sensor that provides information on machine status and production rate. Information is sent to the server via Ethernet or WiFi.

Configure parameters for data analysis using the software package. The MUR system can show stoppage categories and duration, MTBF , hourly production output, Gantt chart with machine efficiency over time, OEE indicator, etc. It can compare days, weeks, machine, production shifts. Configuration options are virtually unlimited.

One of the main advantages of the MUR System is the ability to show performance indicators on the computer screen and on a mobile phone in real time. Mere visualization of work performance often leads too increase in factory efficiency by up to 5%.

Case Study – implementation of MUR in a coating industry